Finned Tubular Heaters

GLOW.jpg)

|

|

|

PRODUCT DESCRIPTION

Finned

Tubular Heaters are normally used in forced circulation heating of low

temperature air, other atmospheres and gases. Typical applications include

forced convection heating of air, process atmospheres, and oven atmospheres in

duct environments. Steel finned tubular heaters are standard with surface

temperatures limited to about 425�C (797�F) compared to 815�C (1500�F) for an

alloy sheathed non-finned heater.

Some applications require

stainless steel materials for corrosion resistance. The most efficient finned

heaters are made with steel sheath and steel fins. Steel is normally used for

air heating, stainless steel for atmospheres which are humid or corrosive and

monel for salt-laden humid atmospheres. Keep in mind that stainless heaters

with stainless fins are very inefficient since the heat transfer rate of

stainless is less than one quarter that for steel. Finned Tubular Heaters offer distinct advantages over open coil heaters: (a) they are safer to operate

in that the risk of fire or electrical shock are minimized; (b) they have a

much longer service life; and (c) they are more rugged requiring less

maintenance than open coil heaters.

We offer a standard

carbon steel construction and a high temperature/ corrosion resistant stainless

steel construction. As with regular tubular elements, they can be bent to a

number of shapes and are available with fittings and mounting brackets as

required. Typical Applications Wattage Required to Heat Air

Flows: http://www.nphheaters.com/quote/industrial_process_heaters/wattage_required.pdf To Order Finned Tubular Heaters

Please Specify:

Bend Formations Below: NPH Tubular Heater Bend Formations.pdf nominal dimensions nominal dimensions nominal dimensions nominal dimensions nominal dimensions nominal dimensions nominal dimensions nominal dimensions nominal dimensions nominal dimensions nominal dimensions nominal dimensions

![]() Finned Tubular Heater Specifications.pdf

Finned Tubular Heater Specifications.pdf

![]() Tubular Heater Bend Formations.pdf

Tubular Heater Bend Formations.pdf

![]() Electric Tubular Heaters Wiring Diagrams

Electric Tubular Heaters Wiring Diagrams

![]() Radiant Heating

Radiant Heating ![]() Convection - Air and Gas

Convection - Air and Gas ![]() Recirculation Ovens

Recirculation Ovens![]() Shrink Tunnels

Shrink Tunnels ![]() Dryers

Dryers ![]() Heat Treating

Heat Treating![]() Annealing

Annealing

![]() Element diameter andsheath material

Element diameter andsheath material ![]() Fin Material

Fin Material ![]() Terminal Type

Terminal Type![]() Total Sheath Length

Total Sheath Length ![]() Cold Section at Each End

Cold Section at Each End![]() Voltage and Wattage

Voltage and Wattage ![]() Bending Configuration Drawings-see link below:

Bending Configuration Drawings-see link below: ![]() Quantity

Quantity![]() Mounting Characteristics and accessories (if required)

Mounting Characteristics and accessories (if required)![]() Special Moisture Resistant Seal (if required)

Special Moisture Resistant Seal (if required) ![]() Bending Formation Drawings – See link below:

Bending Formation Drawings – See link below:

How To Order Finned Heaters

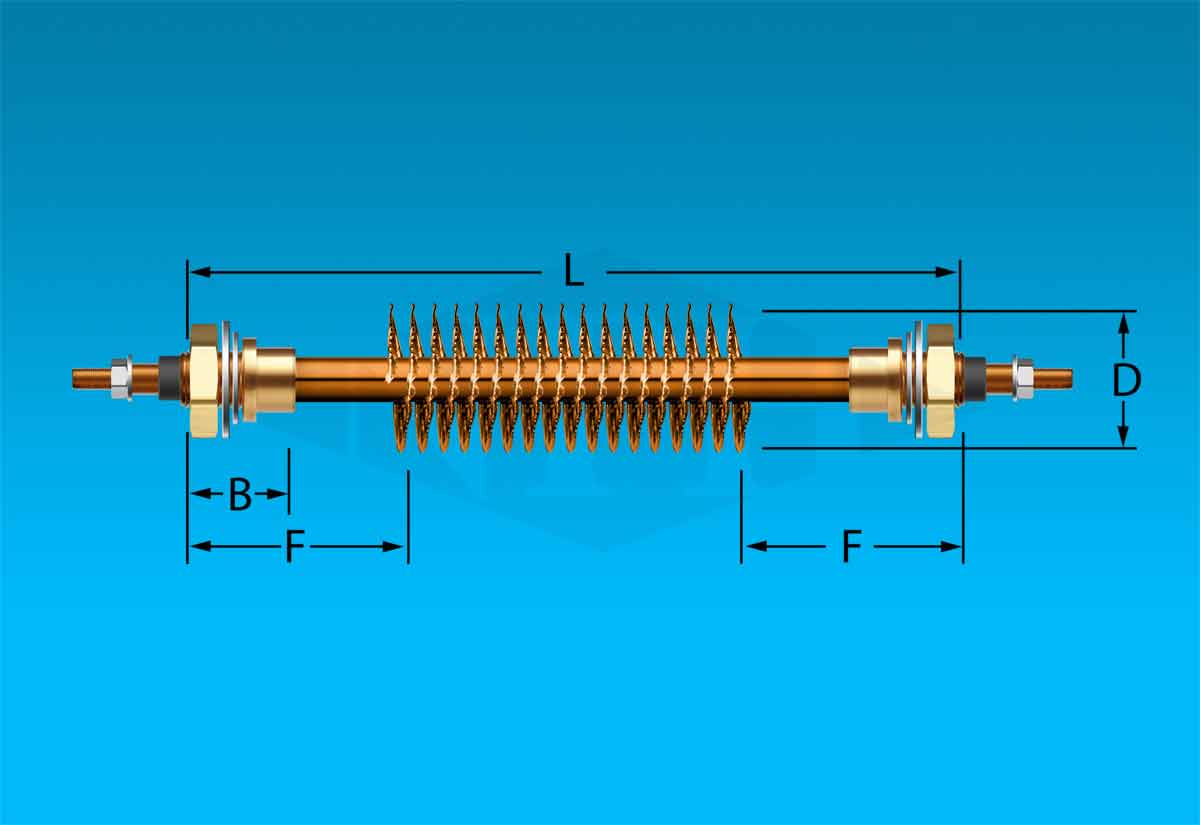

Finned Tubular Element:1

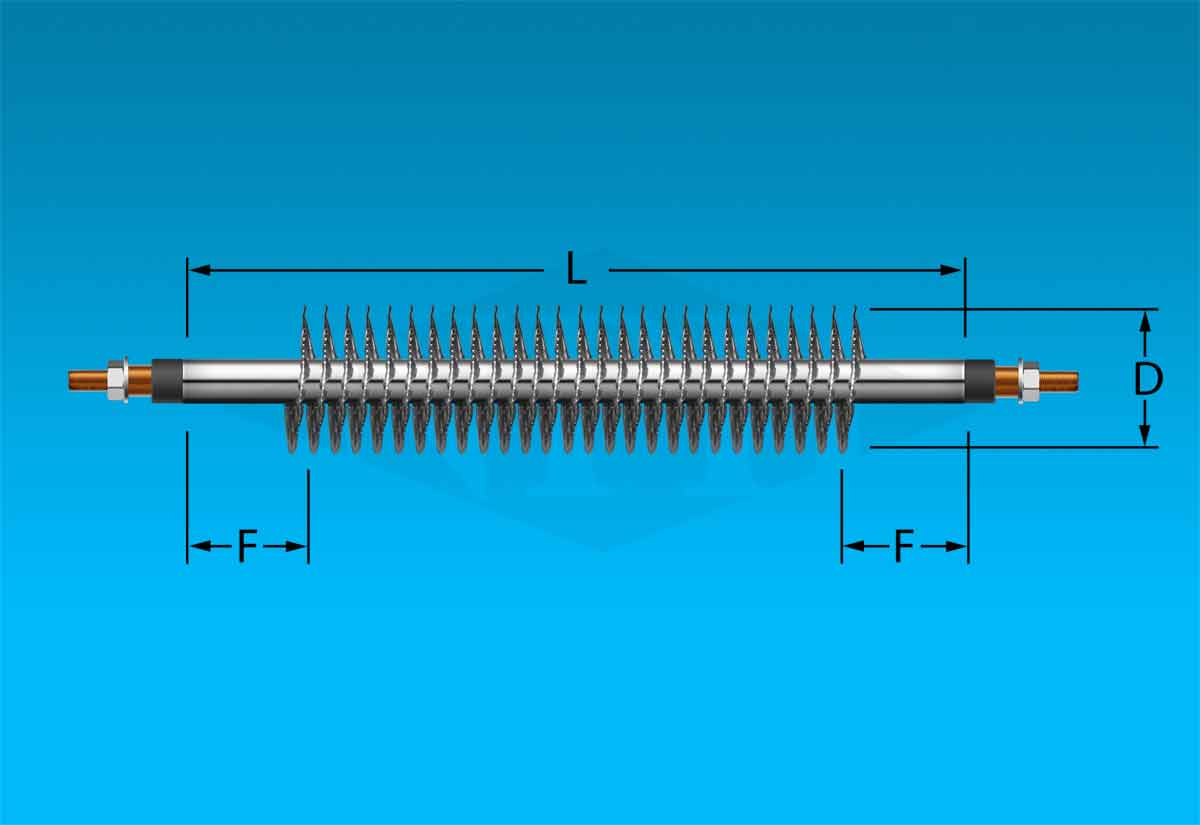

Figure 1 - 0.315"

kw

L

part no.

1

2

3

4

5

6

19

34

49

64

79

94

ASB-301S

ASB-302S

ASB-303S

ASB-304S

ASB-305S

ASB-306S

F = 5/8"

Figure 1 - 0.430"

kw

L

part no.

2

3

4

5

6

7

8

27

39

52

64

77

89

102

ASB-402S

ASB-403S

ASB-404S

ASB-405S

ASB-406S

ASB-407S

ASB-408S

F = 5/8"

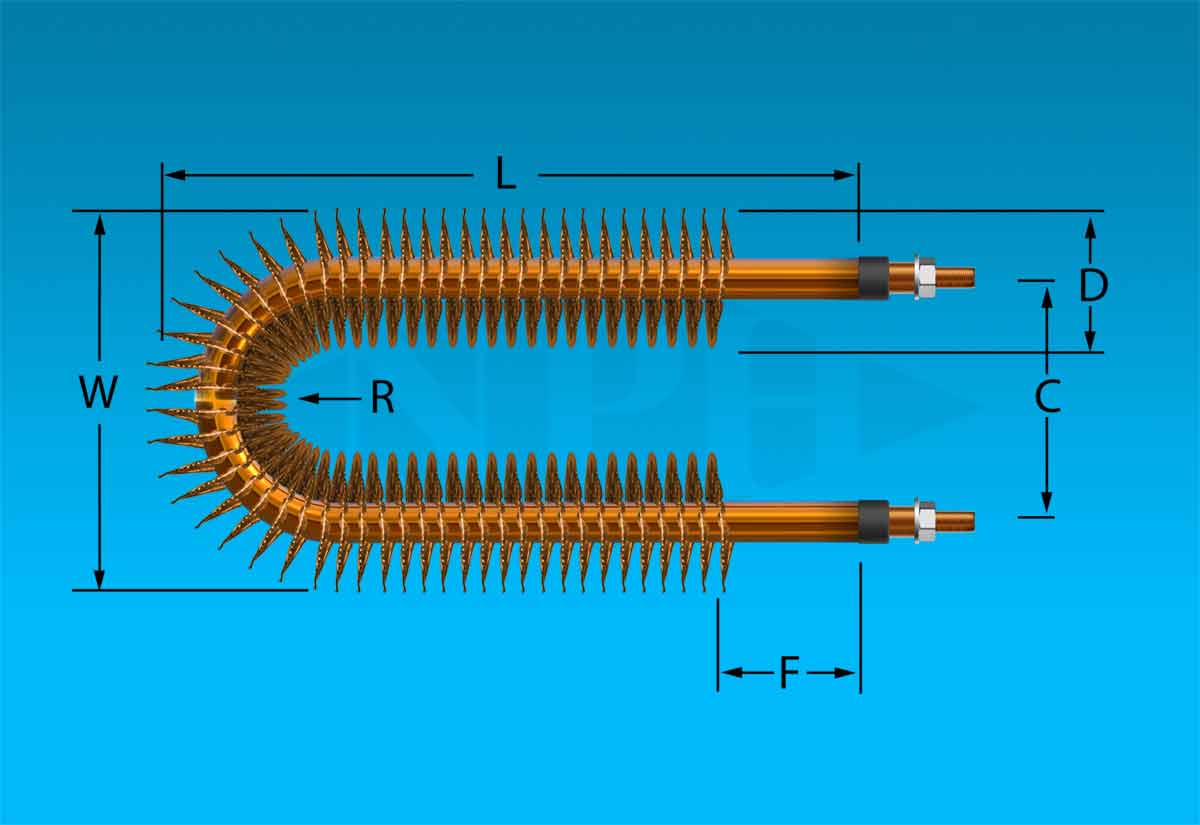

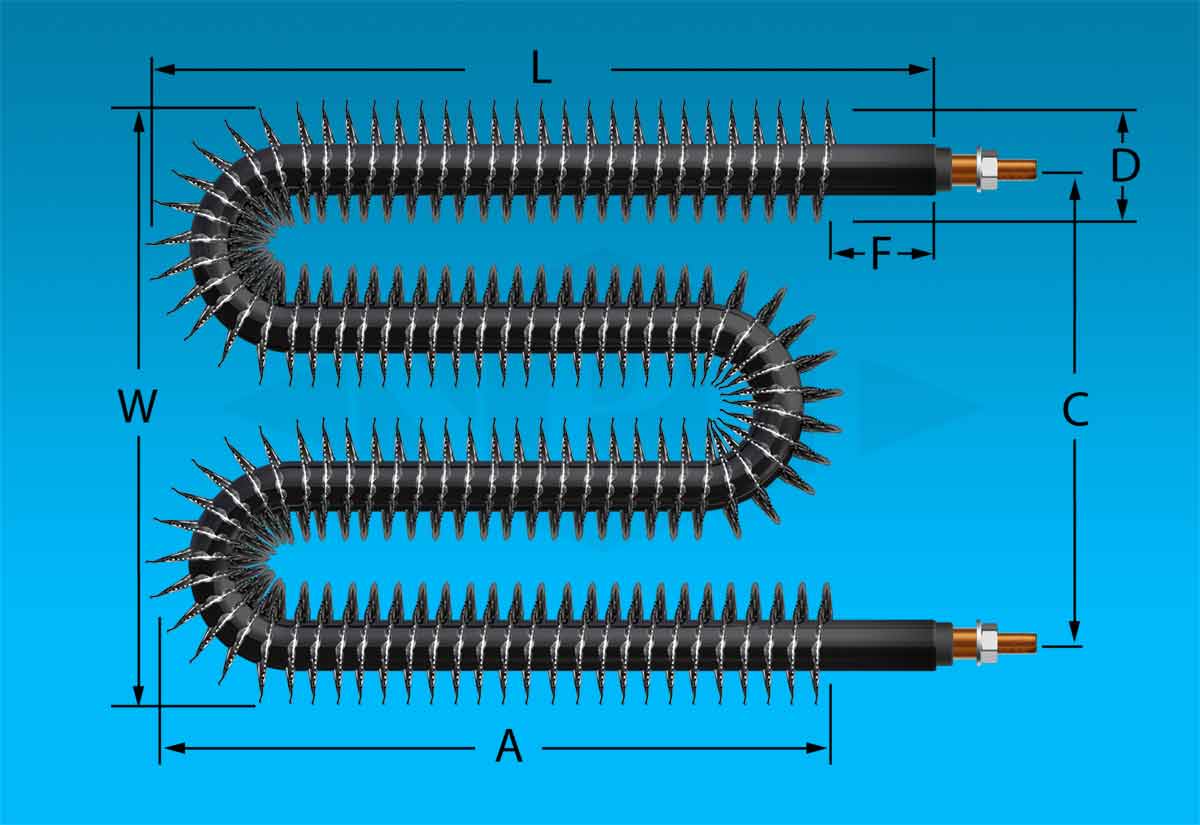

Figure 2 - 0.315"

kw

L

part no.

1

2

3

4

5

19

16

24

31

39

ASB-301U-A

ASB-302U-A

ASB-303U-A

ASB-304U-A

ASB-305U-A

C = 2 1/2"

F=5/8"

R = 1 9/16"

W = 3 3/8"

Figure 2 - 0.430"

kw

L

part no.

2

3

4

5

6

7

8

13

20

26

32

38

44

51

ASB-402U-A

ASB-403U-A

ASB-404U-A

ASB-405U-A

ASB-406U-A

ASB-407U-A

ASB-408U-A

C = 3"

F=5/8"

R = 2"

W=4"

Finned Tubular Element:3

Figure 3 - 0.315"

kw

L

part no.

1

2

3

4

5

6

10

13

17

20

ASB-301W

ASB-302W

ASB-303W

ASB-304W

ASB-305W

A=L-F

C=4½"

F=5/8"

W=5½"

Figure 3 - 0.430"

kw

L

part no.

2

3

4

5

6

7

8

7

10

14

17

20

23

26

ASB-402W

ASB-403W

ASB-404W

ASB-405W

ASB-406W

ASB-407W

ASB-408W

A=L-F

C=6"

F=5/8"

W=7 1/8"

Figure 4 - 0.315"

kw

L

part no.

1

2

3

4

5

6

20.5

35.5

50.5

65.5

80.5

95.5

ASB-301SF

ASB-302SF

ASB-303SF

ASB-304SF

ASB-305SF

ASB-306SF

F=2 1/8"

Figure 4 - 0.430"

kw

L

part no.

2

3

4

5

6

7

8

28.5

40.5

53.5

65.5

78.5

90.5

103.5

ASB-402SF

ASB-403SF

ASB-404SF

ASB-405SF

ASB-406SF

ASB-407SF

ASB-408SF

F=2 1/8"

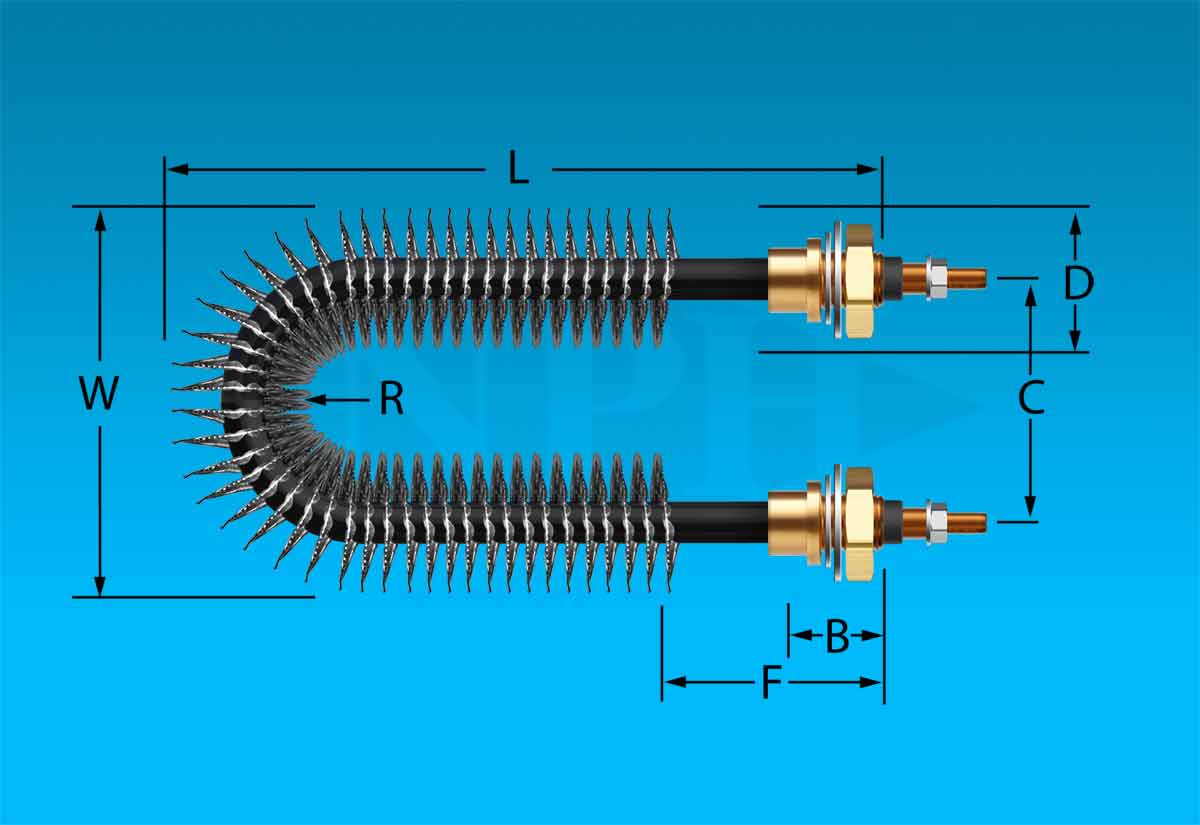

Figure 5 - 0.315"

kw

L

part no.

1

2

3

4

5

6

10.5

17.5

25.5

32.5

40.5

47.5

ASB-301UF

ASB-302UF

ASB-303UF

ASB-304UF

ASB-305UF

ASB-306UF

C=1½"

F=2 1/8"

W=2½"

Figure 5 - 0.430"

kw

L

part no.

2

3

4

5

6

7

8

14.5

21.56

27.5

33.5

39.5

45.5

52.5

ASB-402UF

ASB-403UF

ASB-404UF

ASB-405UF

ASB-406UF

ASB-407UF

ASB-408UF

C=2"

F=2 1/8"

W=3 1/8"

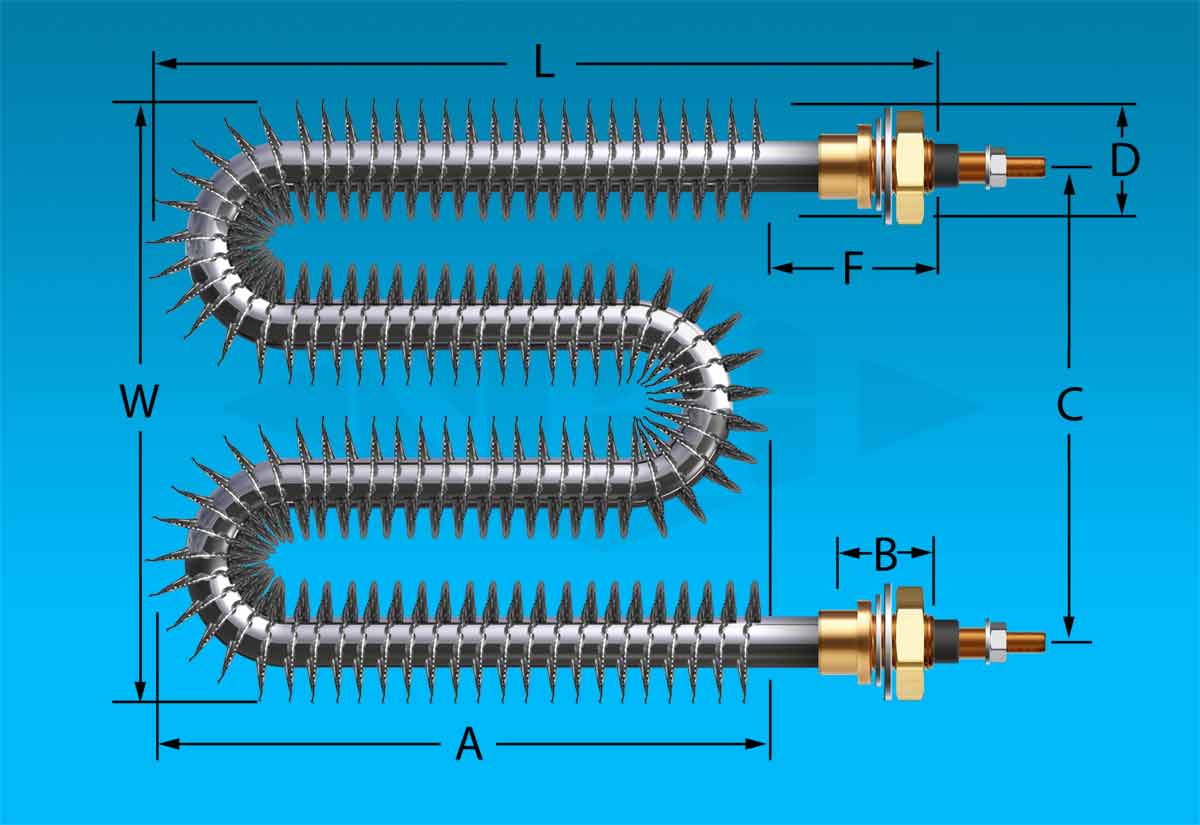

Figure 6 - 0.315"

kw

L

part no.

1

2

3

4

5

6

7.5

11.5

14.5

18.5

21.5

25.5

ASB-301WF

ASB-302WF

ASB-303WF

ASB-304WF

ASB-305WF

ASB-306WF

A=L-F

C=4½"

F=2 1/8"

W=5"

Figure 6 - 0.430"

kw

L

part no.

2

3

4

5

6

7

8

8.5

11.5

15.5

18.5

21.5

24.5

27.5

ASB-402WF

ASB-403WF

ASB-404WF

ASB-405WF

ASB-406WF

ASB-407WF

ASB-408WF

A=L-F

C=6"

F=2 1/8"

W=7 1/8"

We Ship Our Industrial Process Heaters To OEM’s & Industry World Wide.

We Ship Our Industrial Process Heaters To OEM’s & Industry World Wide.

Email:

Email:  Tel:

Tel: